Determining what thickness of head gasket to use on a modified 951 motor was a bit of a trip down a rabbit hole. The information scattered about the internet had a wide variation of opinions on what to actually use. I eventually had a lengthy discussion with a well respected engine builder about exactly what thickness to choose and why to choose it.

But first a little background as to why I thought I might have needed a thicker gasket in the first place. The cylinder head that is to be used for this project was originally a Lindsey Racing Stage 2 with LR springs and moly retainers. In addition it was o-ringed for the stock 100mm bore size. The problem was Cometic MLS head gaskets should not be run with a o-ringed cylinder head.

This is a quote directly from the Cometic website in the technical support section:

Can MLS head gaskets be used with motors setup with o-rings or receiver grooves around the cylinder bores?

No. MLS head gaskets require smooth, flat and true head and deck surfaces to seal. Most of the time with o-ring setups the wire and groove fall where our gasket’s combustion seal is located; therefore, the wire will hold the gasket and not allow proper compression while the receiver grooves allow combustion gases to escape."

So the first problem to solve was machining the old cylinder head down to a flat surface below the o-ring grooves so that the new gasket will seat properly. This required the removal of .03" of material, leaving the cylinder head at 22.83mm as measured from the factory "L shaped" measuring point A. For reference a stock cylinder head is 24mm +/- .1mm

This reduction in cylinder head height had me concerned about the overall impact on the engine compression ratio and engine timing.

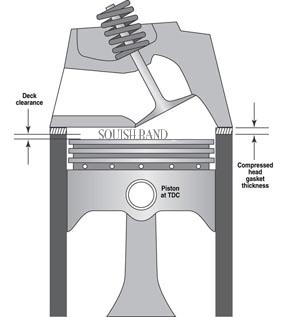

However, it turns out that in reality the real critical dimension for these engines is actually the piston to deck clearance. As the name suggests its the measurement of the piston at TDC vs the height of the deck. Negative numbers mean the piston is below the deck, positive above.

There are a bunch of different ways to obtain this measurement but this is how I did it. I brought the cylinder piston to TDC with dial gauge and bridge via sweep method, taking the measure along the center line. Zeroed the dial for the TDC level. Then I moved the dial gauge over to the deck, over the centerline and recorded the difference. I took a measure at both the piston front and rear.

As long as the you have zero to negative piston to deck clearance you can and should use a stock thickness (.0433") gasket to maintain the ideal quench/squish. A good write up about quench can be seen here. In short .04" is the magic number If the compression ratio is increased as a result of keeping near it, most likely it can be handled in a better way with engine management. For my particular build since I'm already outside the scope of the stock management with the increased bore size the standalone system will easily be able to accommodate the adjustment.

His advice was confirmed in Turbocharging Performance Handbook by Jeff Hartman that I had on the shelf. On page 86 he discusses installing thicker head gaskets and the squish effect very briefly saying:

"Worst of all, it could degrade the "squish" effect in the combustion chambers, which can actually be a greater pro-knock factor than a little more compression.... It is critical that a compression lowering strategy not mess with the squish ring."

When you have positive values (ie: the piston is actually protruding above the deck at TDC) then you will need to go to a thicker gasket by adding the clearance number to .0433" to get the ideal size.

Using the Summit Compression Calculator I was able to find the new compression ratio with the following information of the build.

Bore: 104mm

Stroke: 78.9mm

Cylinder Head Volume: 48.5cc

Effective Dome Volume: 33.4cc

Deck Clearance: -.009in

Compressed Gasket Thickness: .045"

# of Cylinders: 4

Results in a 8.47:1 Static Compression Ratio.

Hopefully this helps clear up some of the misinformation floating around the internet.

No comments:

Post a Comment